Mobile electronics such as telecommunications equipment as well as the electronics in motor vehicles require increasing packing density and thus arrangement of the circuits in multiple layers.

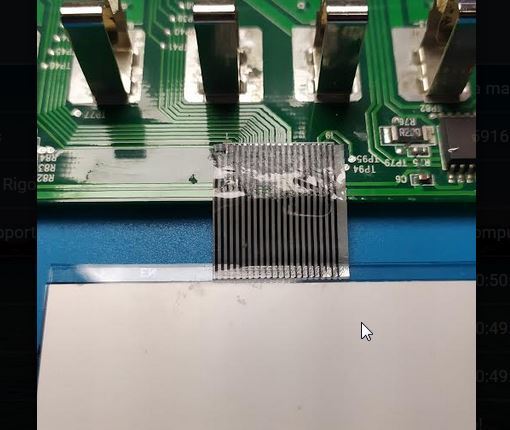

Hot bar soldering flex circuits.

The benefits of hot bar reflow soldering.

The connection of the layers are favorably produced with flexible circuit carriers and or foil connectors these connections are prepared mostly by hot b ar reflow soldering.

Flex circuit to pcb.

Fine pitch sm devices.

The required process energy is supplied by a thermode also know as a hot bar.

Hot bar reflow soldering bonding fundamentals technical articles and whitepapers blogs videos training information and more.

3 layouts for hot bar reflow soldering.

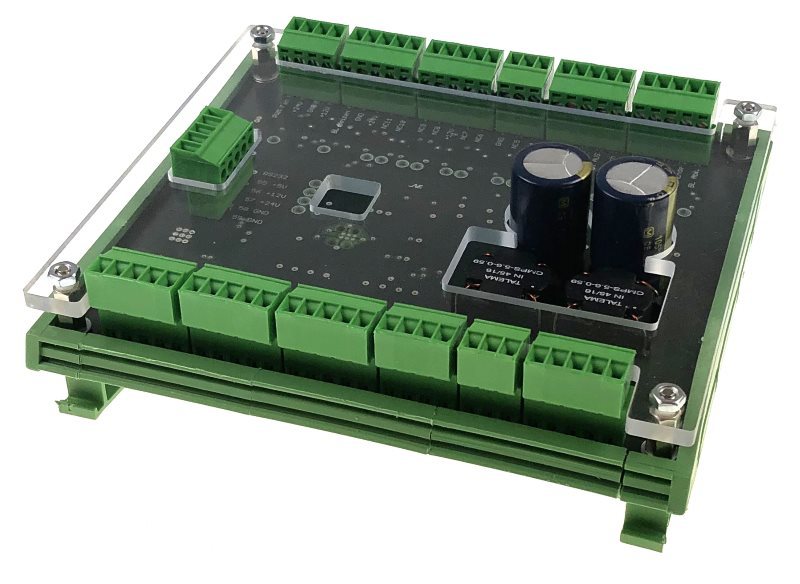

Uniflow 4 provides targeted heating and precision temperature control for hot bar soldering applications such as the connection of flexible circuits ribbon cables wires smt components single or dual sided edge connectors and thermocompression bonding of gold ribbon.

Edge connectors to pcb.

Flex carriers and foil connectors.

Hot bar soldering systems.

The joining technology results in a permanent electro mechanical joint.

1 lead free compatible hot bar process of flex to pcb can replace more costly flex printed circuits and save the cost of pcb connectors.

Typical examples of applications are connecting flex foils to printed circuit boards small wires small coax cables and very light or small components.

Hot bar reflow soldering systems.

2 customized soldering head press all of the soldering joints of parts on pcb to solder it simultaneously by heating them to a temperature it greatly improve soldering efficiency.

The three most common flex circuit termination designs for successful pulse heated reflow soldering are exposed lead single sided and open windowed choose the one that best suits your design and manufacturing needs.

Of soldering the sensor to the flex circuit.

Ribbon cable to pcb.

Tab to pcb hsc to lcd or tab.

Accurate positioning of the parts.

Pulsed heat thermode hot bar soldering is a joining technology where two pre tinned parts are heated to the melting point of the tin.

Manncorp now has the solution to these tough soldering challenges.

Exposed lead both sides of the polyimide material are removed leaving the traces free of insulation.

The primary tools include.

Hot bar reflow soldering is achieved when two pre fluxed solder or adhesive coated parts are heated causing the solder to melt flow and then.

Hot bar soldering is extremely effective in bonding components and parts that are dissimilar and difficult to unite.

Closed loop temperature control.

Process also conserves vertical height of assemblies.

Applications of hot bar reflow soldering.

Typical hot bar reflow soldering applications include flex circuits ribbon cables wires flex to pcb flex to lcd and thermocompression bonding of gold ribbon as found in the telecommunications computer automotive display industries and more.

Fast temperature ramp up and cool down.

Design tips for successful hot bar reflow soldering.