When subjected to shear force or vibration this space allows the screw to move in the path of least resistance.

Shear force on metal roof screws from thermal expansion.

This type of joint is common in the structural steel construction industry and may be referred to as a friction type or slip critical joint.

The coefficient of expansion is constant for all metal thicknesses.

1 the forces in elastic layers are.

Tapping screws are externally threaded fasteners with the ability to tap their own internal mating threads when driven into metallic materials.

The sinuloc threads eliminate this space.

The following design resources are for design screws and bolts for the proper torque stress strain preload and other engineering critical design parameters.

The expansion coefficient for steel is 12 10 6 m mk 6 7 10 6 in in o f.

Screws can also be used for connections in steel framing systems and roof trusses.

The joint be tween layers l and 3 will have thickness 7 and shear modulus g.

The joint between layers 1 and 2 will have thickness 7 and shear modulus g.

However for the local area diaphragm framing is a far more typical construction practice.

Screws can provide a rapid and effective means to fasten steel metal siding and roofing to framing members.

The shear forces have to overcome the friction developed by the clamp load which in most cases will be far more than the actual shear strength of the fastener itself.

With the temperature cyclically changing if there is a mismatch between the thermal expansions of the bolt and joint expansion induced radial shear stress can weaken the friction torques and finally causes bolted joints to loosen.

For example 24 gauge galvanized steel has the same coefficient of expansion as 26 gauge galvanized.

By simultaneously pushing on both the pressure and the trailing flanks of the joint the fastener creates prevailing tension within the joint itself.

Elastic moduli e e e3 and thermal expansion coeffi cients a a a.

6 in steel pipe with length 50 m 1969 in is heated from 20 o c 68 o f to 90 o c 194 o f.

Torque and stress strain calculation and formula.

Developed by emseal over 20 years ago shear pockets are a loop of santoprene thermoplastic rubber welded to replace the center member or cells of an expansion joint extrusion.

Agreeably if i used structural metal roofing with a braced roof system as hokie66 proposes i can increase my purlin spacing because structural metal roofing allows for much longer span ratings.

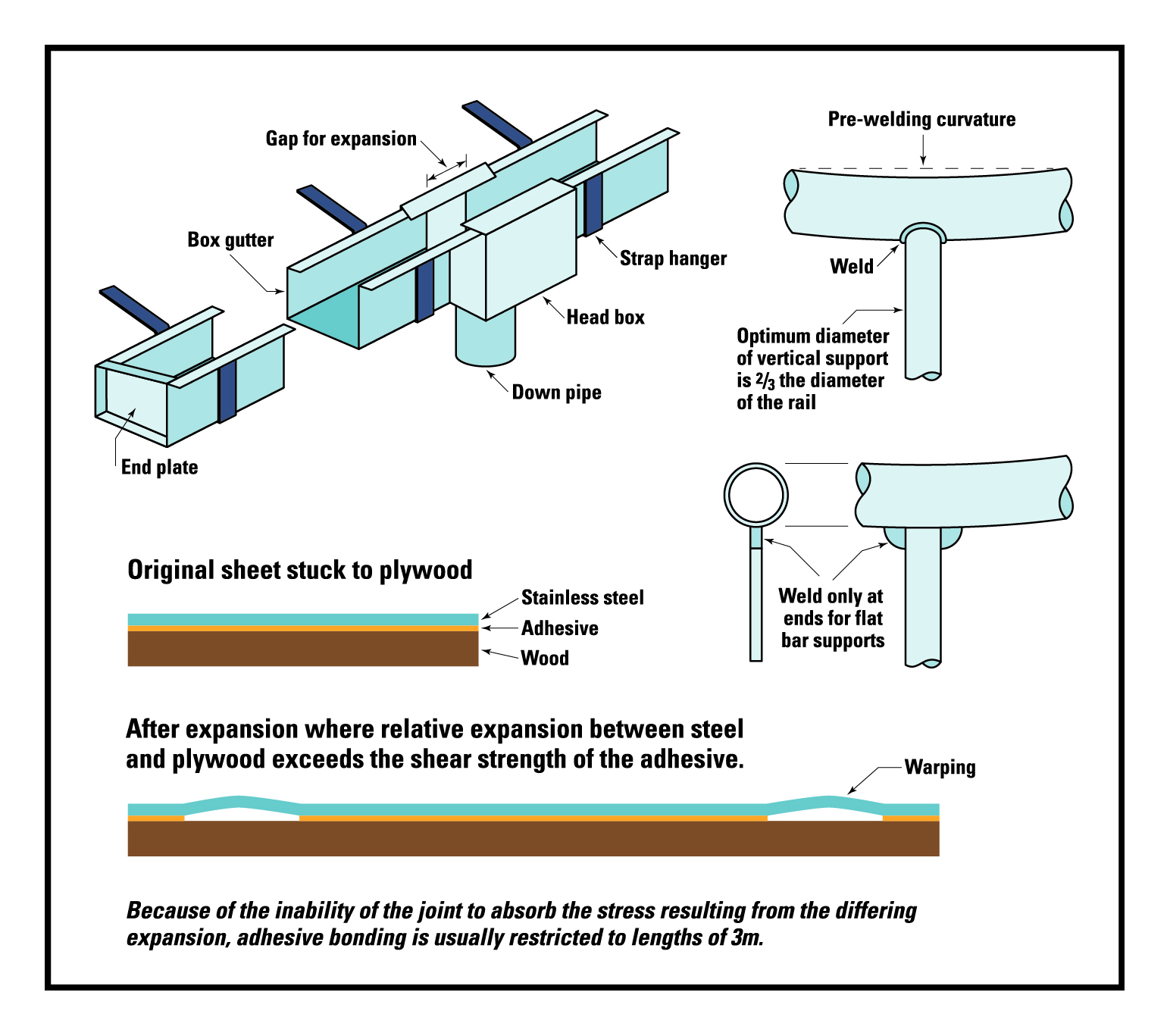

Ture and ce is the coefficient of expansion for each metal can provide the amount of expansion and contraction in common roofing materials see figure 1.