Abaqus routine and advanced simulation linear and nonlinear static and dynamic thermal electrical acoustics.

Sheet metal forming simulation abaqus.

Nanoprecision products inc 411 b coral circle el segundo ca.

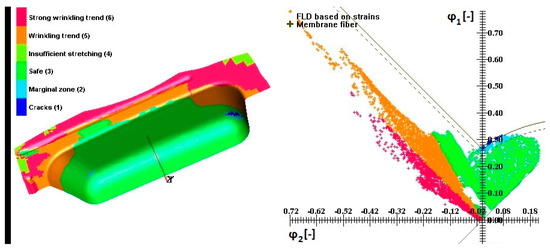

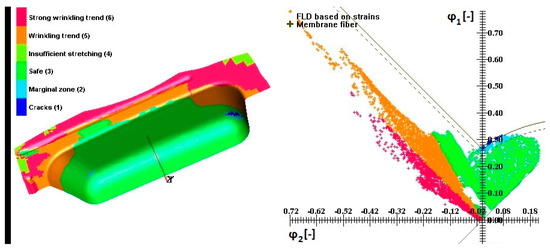

Finally some proposals to overcome these defects are presented.

Abaqus routine and advanced simulation linear and nonlinear static and dynamic thermal electrical acoustics.

Adaptive 3d remeshing for metal forming simulation s.

The sheet metal is modelled as a shell.

Only a quarter of the geometry is simulated for reasons of symmetry.

Excessive element distortion in 3d large deformation analyses.

Simulations were used to optimize tooling.

The shape of the blank the sheet metal is shown below.

They gradually change shape to make the profile increasingly more pronounced the rollers have a grap between them with a width of 2 mm.

It is a flat strip that is 3 2 m long 40 cm wide and 1 5 mm thick.

Abaqus acumen 41 220 views.

Manufacturing simulation sheet metal bending abaqus cae implicit standard duration.

Kim s w lee h.

Eight sets of rollers are used to shape the material.

Course objectives in this course you will learn practical modeling skills and techniques for.

The mesh is shown below.

M s joun finite element simulation of plate or sheet metal forming processes using tetrahedral mini elements journal of mechanical science and technology vol.

Metal forming with abaqus abaqus 2018.

Metal forming with abaqus 2017.

As an example to test the ductile failure idea the finite element simulation of a metal forming process was made in abaqus.

Course objectives in this course you will learn practical modeling skills and techniques for.

237 243 2014 14 digital removable partial dentures models labmagic 3d cad 2015.

Although the simulation of this kind of problem is successful some inherent defects of abaqus are found.