In bending and embossing of sheet metal the female die is replaced with rubber pad rubber pad forming rpf is a metalworking process where sheet metal is pressed between a die and a rubber block made of polyurethane.

Sheet metal joining operations.

Most engineers rely heavily on mechanical fasteners.

How to join sheet metal parts.

We specialize in technologies including self piercing riveting punch riveting and full pierce riveting.

Screw joint in sheet metal.

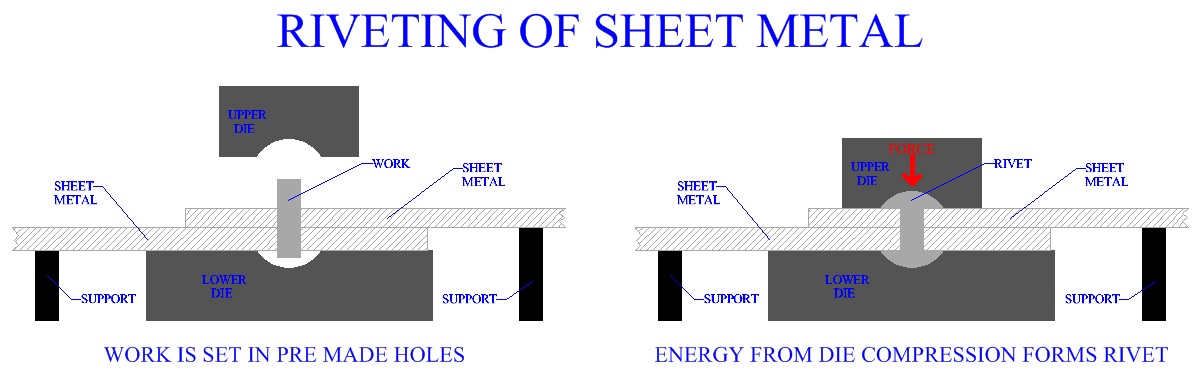

Prior to riveting adjacent holes are punched.

The riveting is carried out in the hole corresponding to the two parts and the rivet gun is used to pull.

In this screws bolts nuts studs and standoff.

Screw joint is a type of temporary joint.

6 types of sheet metal joining techniques folding tab joints.

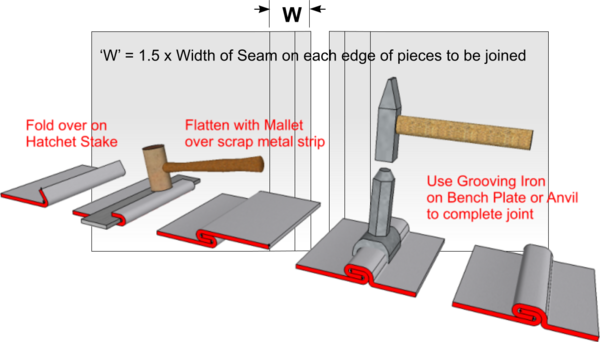

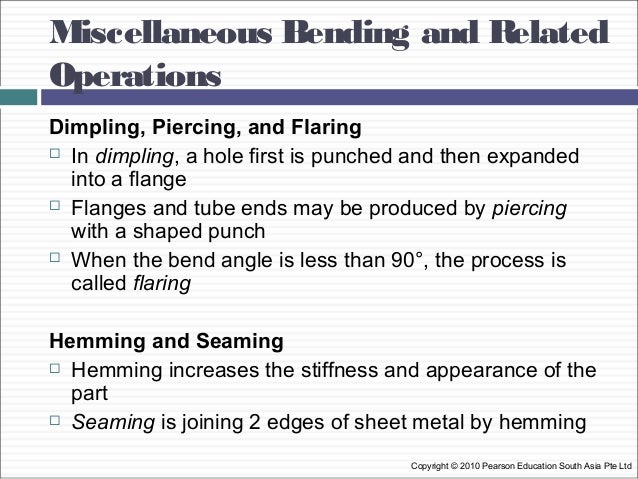

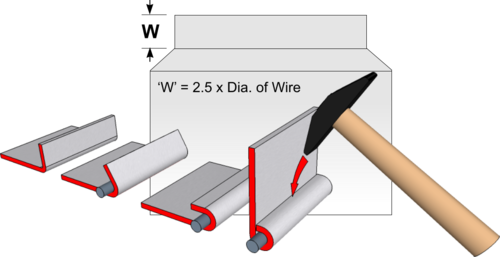

Hemming is the process in which the edge is rolled flush to itself while a seam joins the edges of two materials.

It leaves a lean edge on the piece of metal is sheared or cut.

Hems are commonly used to reinforce an edge hide burrs and rough edges and improve appearance.

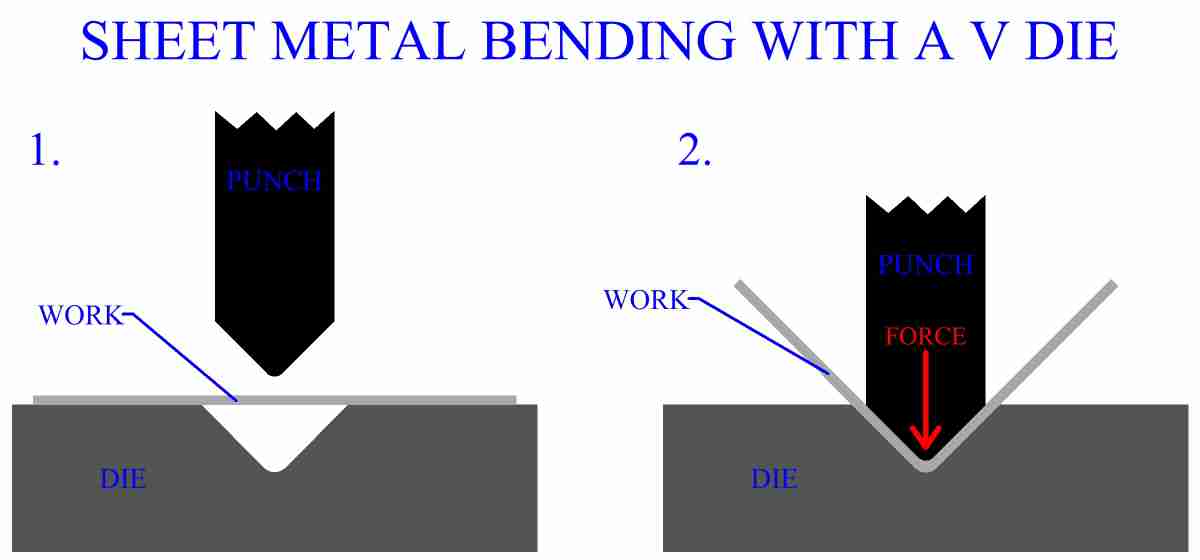

In this operation a sheet metal workpiece is placed or kept between two dies from one end.

Sheet metal operation gives many advantages over forging or casting process which makes it a most versatile operation.

Under pressure the rubber and sheet metal are driven into the die and conform to its shape forming the part.

One benefit of clinching is the capability to join prepainted sheet metal commonly used in the appliance industry without damaging the painted surface.

And the punch is hit at the other end of the sheet producing a shearing effect.

It is a cut in a straight line across a strip sheet or bar.

Sheet metal joining techniques 1.

Joining sheet metal with elements tox pressotechnik offers the systems and technology competence for different riveting operations which can all be summed up as.

Clinching is an important means of fastening aluminum panels such as hoods and decklids in the automotive industry due to the difficulty of spot welding of aluminum.

Riveting is a type of permanent joining operation.

These products have good strength with light weighted characteristic versatility in shapes low cost fast production rate and many more advantages which make is suitable for every manufacturing industries.

A thin sheet like galvanized sheet may be joined to another mechanical process by riveting and by soldering to soft soldering.

Which is best depends on the material its thickness and the application requirements.

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself.