Plate in general terms we can say that anything 1 8 and thicker is a plate and anything less than 1 8 is a.

Sheet of metal passing through rollers is stronger why.

The area of greatest deformation lies on line ff just behind the location of the smallest gap between the rollers.

In metalworking rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform.

Sheet metal forming between rolls to determine the designation of sheet vs.

It s also called the plunge a technique for removing strip memory see figure 4.

This forces the material to pass through extreme angles to erase memory caused by trapped internal stresses.

The gap between the rolls is set independently on a leveler s entry and exit.

An example of possible static charging is a continuous sheet of paper passing over a natural rubber roller as shown below.

The sheet metal rolling process consists of passing metal stock through one or more pairs of rolls to reduce the thickness and to make the thickness uniform.

The concept is similar to the rolling of dough rolling is classified according to the temperature of the metal rolled.

The rolling is a process which consists of passing the metal through a gap between rollers rotating in opposite direction.

A leveler uses.

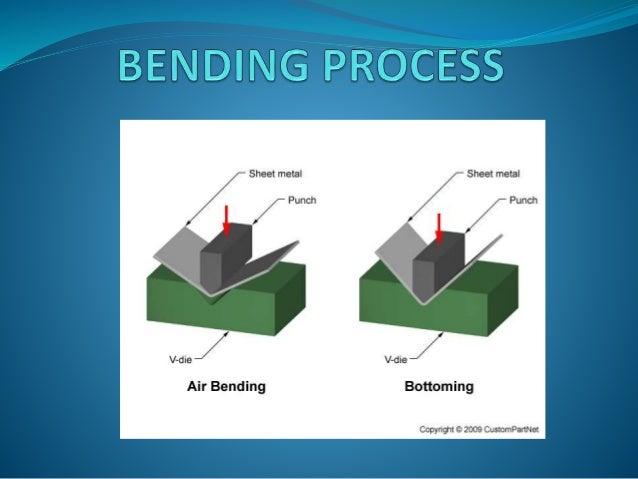

This gap is smaller than the thickness of the part being worked.

If the temperature of the metal is above its recrystallization temperature then the process is.

Therefore the rollers compress the metal while simultaneously shifting it forward because of the friction at the roller metal interfaces.