Support brackets can be fabricated and provided to introduce the vertical loads into the sheet pile wall and simultaneously assist with mounting the waler onto the face of a wall ll.

Sheet pile wall waler design.

A sheet pile wall is required to support a 12 excavation.

Donald douglass and john northrop transformed airframe design by using the skin of the airplane for load distribution in the dc 3.

In the past the global safety factor was the rule.

Foundation engineering sheet pile walls designing of sheet piles mainly is to calculate the depth of penetration d and determining the section of sheet pile as will be discussed later.

The design procedures included in this manual are in common use today by most.

Now we will learn how to analyze and design each type.

One factor applied to the steel sheet piles and one applied to the geotechnical design usually applied to the passive resistance of the soil.

Three basic types of sheet pile structures are considered.

Waler joints can be used to connect sections of waler beam together.

The waler system consists of two beams welded along the sheet piles near the top one on each leg of the l.

Soil conditions may allow for the sections to be vibrated into ground instead of it being hammer driven.

The waler system with its distributed load design has reduced the load on the concrete structure by 80.

There is a corner brace that spans between the two beams making each beam what i would call simply supported with a cantilevered overhang.

The full sheet pile wall is formed by connecting the joints of adjacent sheet pile sections in sequential installation.

Sheet pile walls are constructed by driving prefabricated sections into the ground.

Waler bolts are required for the transmission of the horizontal forces from the sheet.

To take into account the friction between the wall and the soil we use friction angle δ φ 2.

Design of cantilevered wall granular soil.

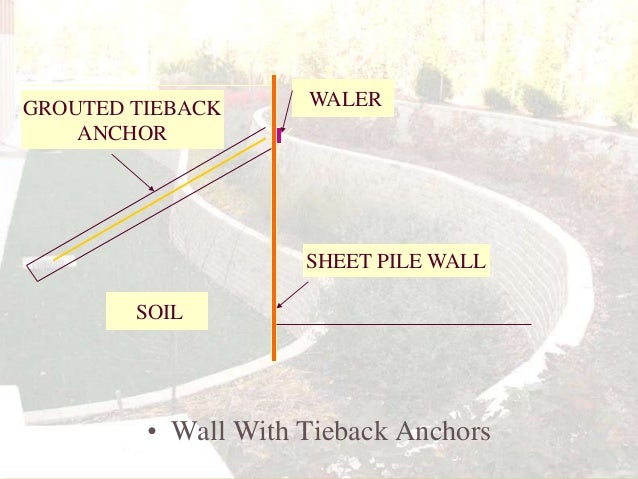

3 cantilevered and anchored retaining walls 2 braced cofferdams and 3 cellular cofferdams.

9 shows an example of.

Consideration is also given to the design of anchorage systems for walls and bracing systems for cofferdams.

Types of sheet piles there are two main types of sheet piles.

Design of wall section æ determine design force for pile the shear and moment distributions on the wall can be constructed from the force diagram first by assuming the wall is rigid with no deflection so that v z z q z dz 0 and m z z v z dz 0 where q v and m are force shear and moment respectively.

The beams welded on the sheet piles will support the anchor force and be in flexure.

Please note this value is applied only for passive pressure.

A row of interlocking vertical pile segments driven to form an essentially straight wall whose plan dimension is sufficiently large that its behavior may be based on a typical.

Design of steel sheet piles there are several methods to design a sheet pile wall.

Below s short description of the most common methods.